function ofPellet Ring Die

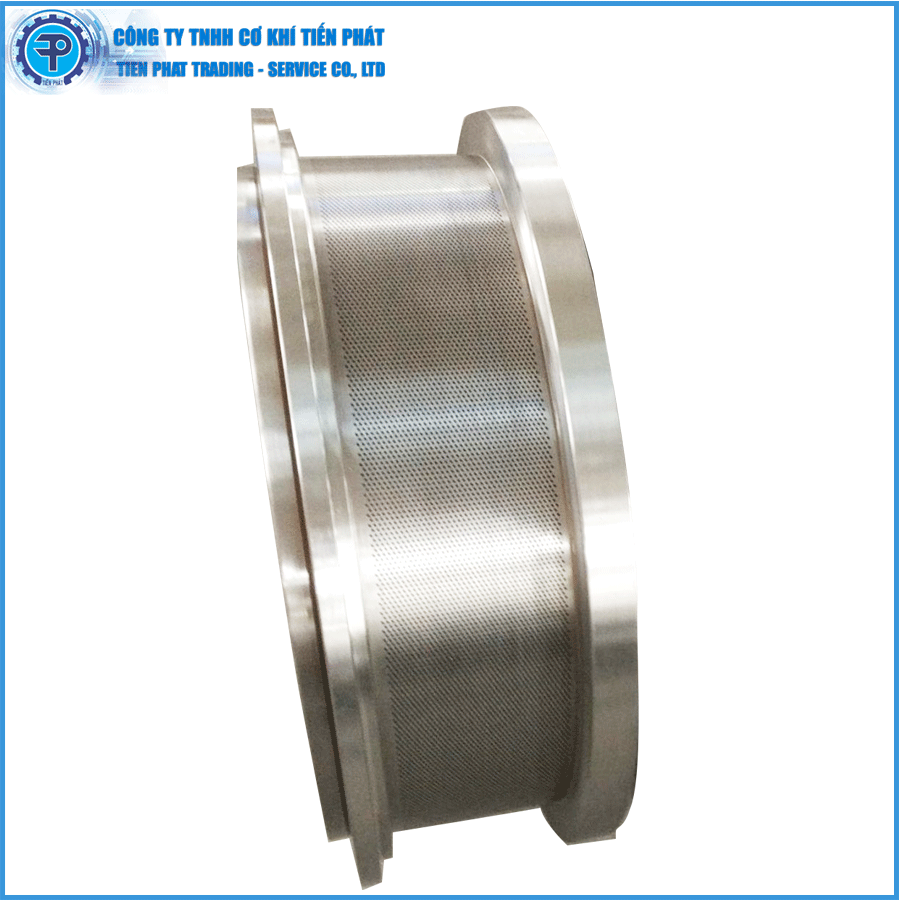

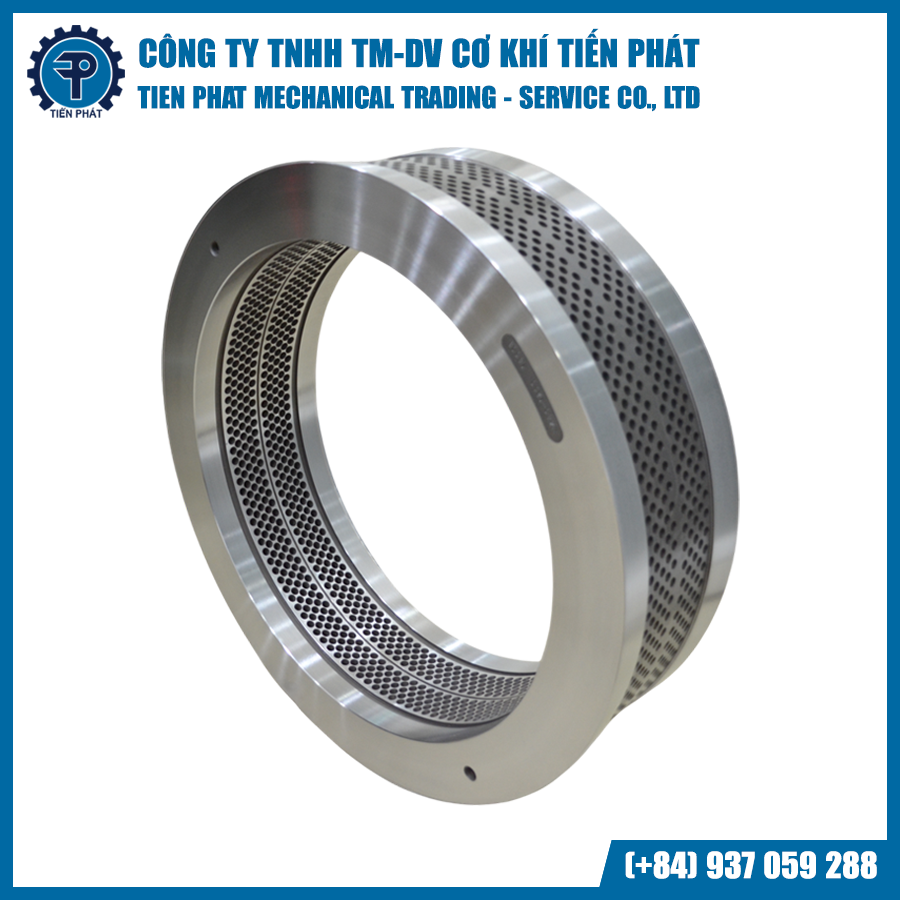

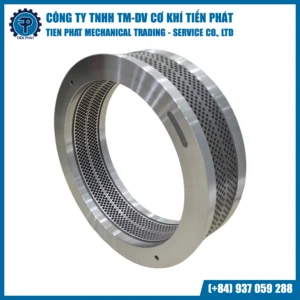

The Pellet Ring Die is the core component of a pellet mill, responsible for forming and producing feed pellets during the pelleting process. The die is designed in a ring shape with precisely machined die holes, allowing conditioned raw materials to pass through under high pressure to produce pellets with uniform size, shape, and durability.

In animal feed and aquaculture feed production, the pellet ring die directly affects output capacity, pellet quality, uniformity, hardness, and digestibility. A properly engineered die made from suitable materials enables stable machine operation, reduces wear, improves energy efficiency, and extends the service life of the equipment.

The pellet ring die is the heart of the animal feed pellet mill. Its quality has a direct impact on machine performance and energy consumption, and it ultimately determines the final output quality of the pellet mill. Therefore, selecting a reliable and reputable pellet ring die manufacturer or machining supplier is a top priority.

Pellet Ring Die Machining at Tien Phat Mechanical

Machining Pellet Ring Dies is a critical technical process in pellet mills, directly determining the shape, uniformity, durability, and overall quality of finished pellets. This process requires extremely high precision and deep expertise. With over 20 years of experience, Tien Phat Mechanical has developed in-depth knowledge of material properties, pellet hole drilling technology, compression ratio design, and practical experience in the animal feed and aquaculture feed processing industry. We select high-quality steel blanks with excellent wear resistance, load-bearing capacity, and heat resistance, suitable for continuous operation under high pressure in pellet mills.

Pellet Ring Dies at Tien Phat Mechanical are precisely machined using advanced CNC systems and modern specialized gun drilling machines, ensuring accurate technical design, high concentricity, uniform hole density, and precisely machined compression zones. This allows stable material compression, producing pellets with consistent size, smooth surfaces, and minimal cracking or breakage. The dies are heat-treated and surface-hardened under strictly controlled processes to optimize mechanical properties, enhance wear and pressure resistance, and significantly extend die service life.

In addition, a strict quality control system is applied throughout the entire manufacturing process, from inspection of overall dimensions, concentricity, pellet hole accuracy, and compression zone geometry to hardness and other critical technical parameters. With the support of modern measuring and inspection equipment, every Pellet Ring Die delivered meets technical requirements and ensures stable, long-term operation.

Tien Phat Mechanical’s pellet dies are compatible with all major pellet mill brands and are widely used in various industries such as animal feed processing, wood pellet production, fertilizer manufacturing, and more.

With over 20 years of experience and strong technical expertise, Tien Phat Mechanical specializes in manufacturing high-quality pellet mill dies. Our products are designed to fit all pellet mill brands and serve multiple industries, including animal feed, biomass pellets, fertilizers, and related applications.

In addition, we provide repair and refurbishment services for used pellet dies, helping customers maximize production performance until the die reaches the end of its service life, thereby optimizing efficiency and reducing overall operating costs.

Technical Specifications

-

Material: Alloy Steel

-

Hardness: 54–56 HRC

-

Heat Treatment: Vacuum heat treatment

-

Types: Customized based on machine models and customer requirements

Ordering & Delivery

Optimized processes to minimize customer downtime:

-

Quotation: Detailed response within 24 working hours

-

Manufacturing Lead Time: 30-60 days, depending on type and raw material

(urgent orders can be expedited) -

Shipping:

-

Domestic: Door-to-door delivery within 2–5 days, depending on location

-

Export: Support for various Incoterms (FOB, CIF, CIP, DDP, etc.) upon request

-

-

Packaging: Rust-preventive oil coating, shrink wrapping, and sealed wooden crates compliant with export standards

Technical Support

Remote online technical support or on-site assistance at the customer’s factory, depending on requirements.

Commitment

With a team of experienced and professional engineers and technicians, Tien Phat ensures finished products with high precision that fully meet technical requirements and respond quickly to customer needs.

We place trust and reliability at the core of our operations and are committed to completing all orders on time while maintaining the highest quality standards. In the event of equipment issues, we pledge to provide prompt solutions and timely support to minimize downtime and losses for our customers.

Contact Information

Tien Phat Trading & Service Mechanical Company Limited

- Head Office: 237A National Highway 1K, Linh Xuan Ward, Ho Chi Minh City, Vietnam

- Branch Factory: No. 3, Cay Tram Residential Area, Tan Khanh Ward, Ho Chi Minh City, Vietnam

- Website: https://cokhitienphat.com

- Email: cokhitienphat@gmail.com

- Phone: (+84) 937 059 288

- Facebook: facebook.com/cokhitienphat

Tiếng Việt

Tiếng Việt

Be the first to review “Pellet Ring Die”