ABOUT

ABOUT US ♥ VISION ♥ MISSION♥ CORE VALUES

ABOUT US

TIEN PHAT MECHANICAL TRADING AND SERVICE COMPANY LIMITED

Tien Phat Mechanical Company Limited was originally established in 2001 as Tien Phat Mechanical Workshop. On March 28, 2005, it was officially registered as Tien Phat Trading & Service Mechanical Company Limited under Business License No. 4102028789 issued by the Ho Chi Minh City Department of Planning and Investment.

Tien Phat Mechanical Company Limited specializes in the design and manufacture of mechanical machinery, mold fabrication, spare parts manufacturing, and precision machining services.

In particular, Tien Phat Mechanical Company focuses on producing equipment and spare parts for extruders, pellet mills, and pulverizers, serving the animal feed and aquaculture feed production industries.

Tien Phat Mechanical Company is a trusted spare parts supplier to many leading domestic enterprises in the animal feed and aquaculture feed manufacturing sector, including GROBEST Vietnam, Con Cò, Viet Thang, GreenFeed, CJ, Woosung, Uni-President, Haid Feed, Dabaco Group, Growmax and others.

Guided by the principle “Dedicated to Contribute – Earning Trust,” we always aspire to accompany and support our customers throughout their production processes. We sincerely look forward to receiving your continued trust and cooperation.

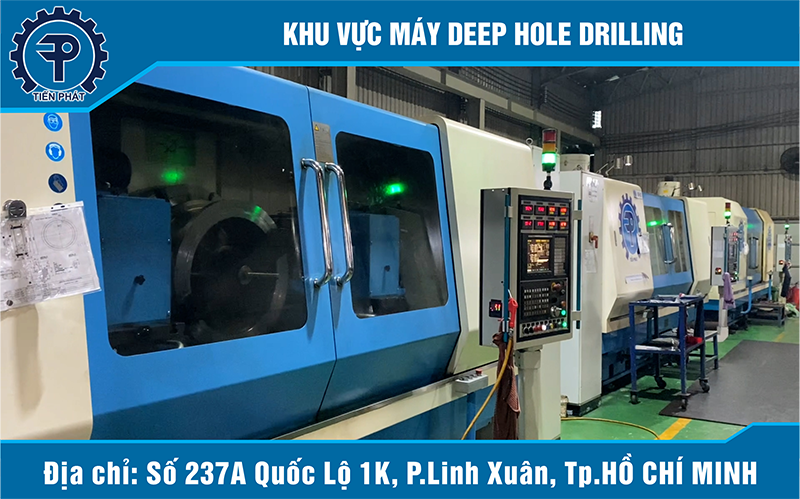

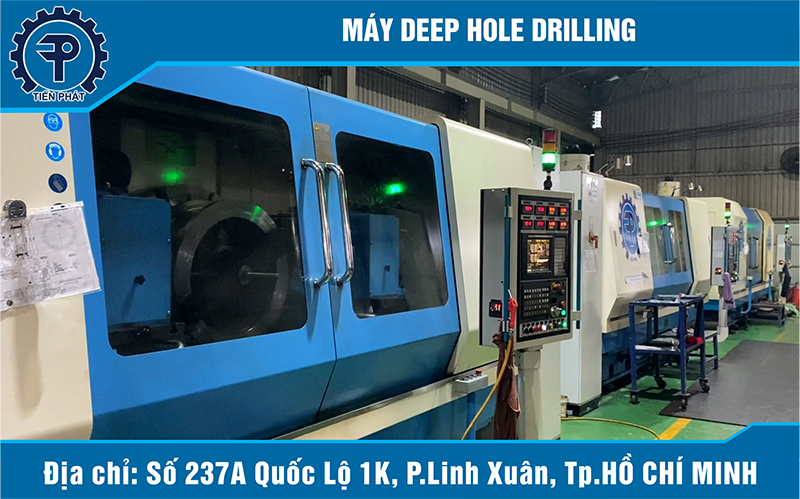

OUR FACTORY & MACHINERY AND EQUIPMENT

We welcome you to explore the manufacturing facilities and machinery of Tien Phat Mechanical Company.

Currently, we operate two manufacturing plants with a total area of over 5,000 m², fully equipped with modern and specialized machinery. Our facilities include 4-axis CNC milling machines, CNC punching machines, CNC wire-cut EDM machines, vertical lathes, vacuum heat treatment systems, deep-hole drilling (gun drilling) machines, turning machines, sleeve machines, and a wide range of other advanced CNC equipment

Our advanced facilities and equipment enable us to maintain full control over production processes and quality management, ensuring high precision, efficiency, and long-term stability. This allows us to effectively meet the increasingly stringent requirements of customers across various industrial sectors.

Tien Phat Mechanical Company, with over 20 years of development, is supported by a dedicated, professional, and highly experienced team of managers, engineers, and technicians, along with a wide range of modern machinery and equipment. As a result, we consistently deliver high-quality products and services to meet the diverse needs of our valued customers..

VISION ♥ MISSION

Tien Phat Mechanical Company strives to become a leading provider of precision machining and machine manufacturing in Vietnam, with a strong focus on producing spare parts for animal feed and aquaculture feed processing machinery. We regard credibility, quality, and customer trust as the foundation for our sustainable development

Guided by the principle “Committed to Excellence – Earning Trust,” the management and all employees of Tien Phat Mechanical Company are committed to delivering high-quality products and services that help our customers optimize time, cost, and operational efficiency in their production processes.

Tien Phat Mechanical Company is always ready to meet all technical requirements, from simple to complex. We continuously improve our technology, enhance product and service quality, and consider customer satisfaction as the key measure of our success.

CORE VALUES

Passion for Innovation: Innovation is a key driver of our company’s growth. We are constantly driven to create new products, unique ideas, and innovative solutions to meet the evolving needs of our customers.

Agility in Technology: The ability to quickly adopt new technologies is essential to maintaining our leading position. We continuously invest in advanced equipment, software, and the latest technical solutions to enhance product quality and strengthen our competitiveness in the market.

Precision in Machining: Product quality is highly dependent on machining and manufacturing processes. We are committed to ensuring precision at every stage of production. Accurate machining enhances product durability and minimizes manufacturing defects.

Strict Quality Inspection: Measurement and inspection are critical steps in ensuring product quality before market release. We apply rigorous inspection procedures and utilize high-precision measuring equipment to guarantee consistent product quality.

Meticulous Finishing: Product finishing is the final and most important step in achieving excellence. We pay close attention to every detail during the finishing process to ensure a flawless product and a strong first impression for our customers.

Imphasis On Integrity and Trust: Upholding our commitments and conducting business with integrity form the foundation of trust with our customers and partners. Credibility is the core value that guides all our actions.

Tiếng Việt

Tiếng Việt