Function of Steam lock – Shear lock

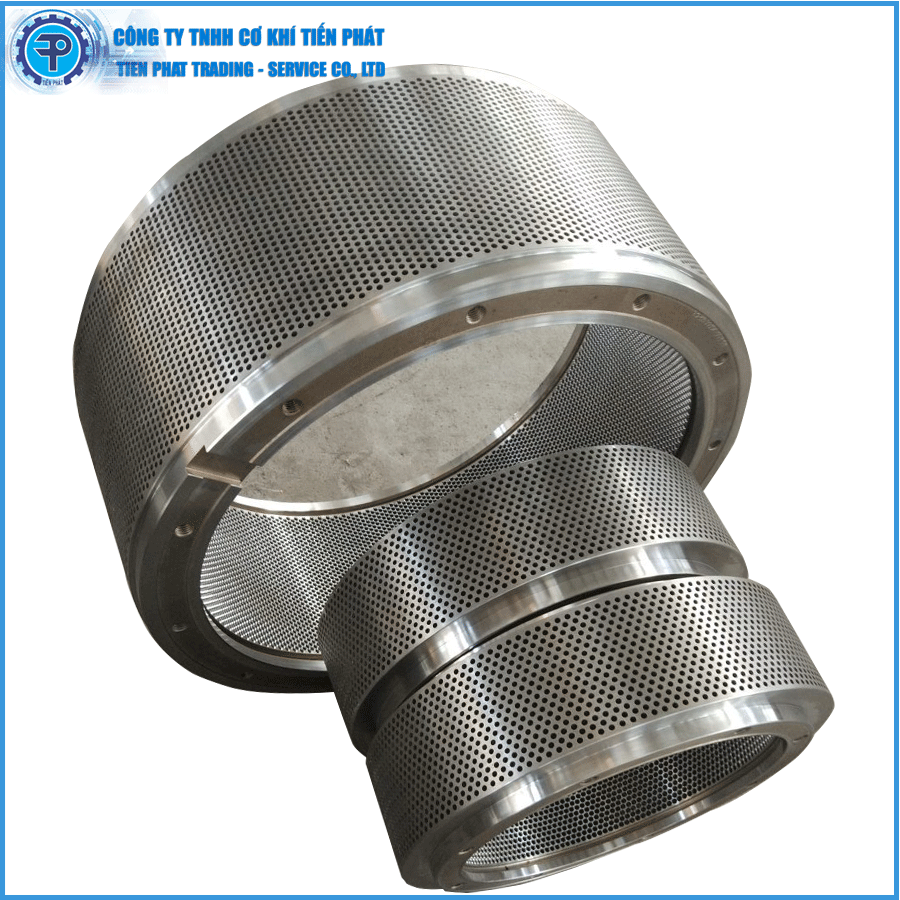

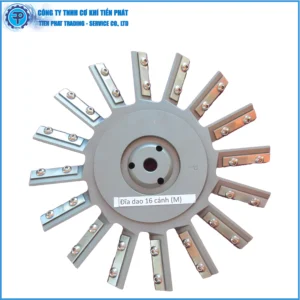

Steam Lock and Shear Lock are two components in extruder machines used for livestock and aquaculture feed processing. These parts are installed within the shaft assembly and extrusion chamber, where they control steam heat flow and pressure, helping to gelatinize and cook the raw materials before they pass through the extrusion die.

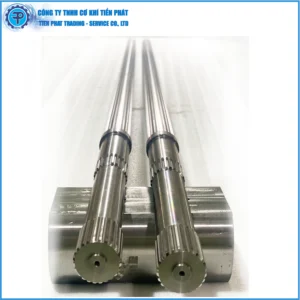

Machining of Steam Lock – Shear Lock at Tien Phat Mechanical

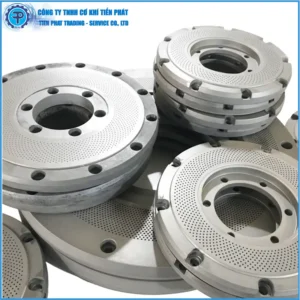

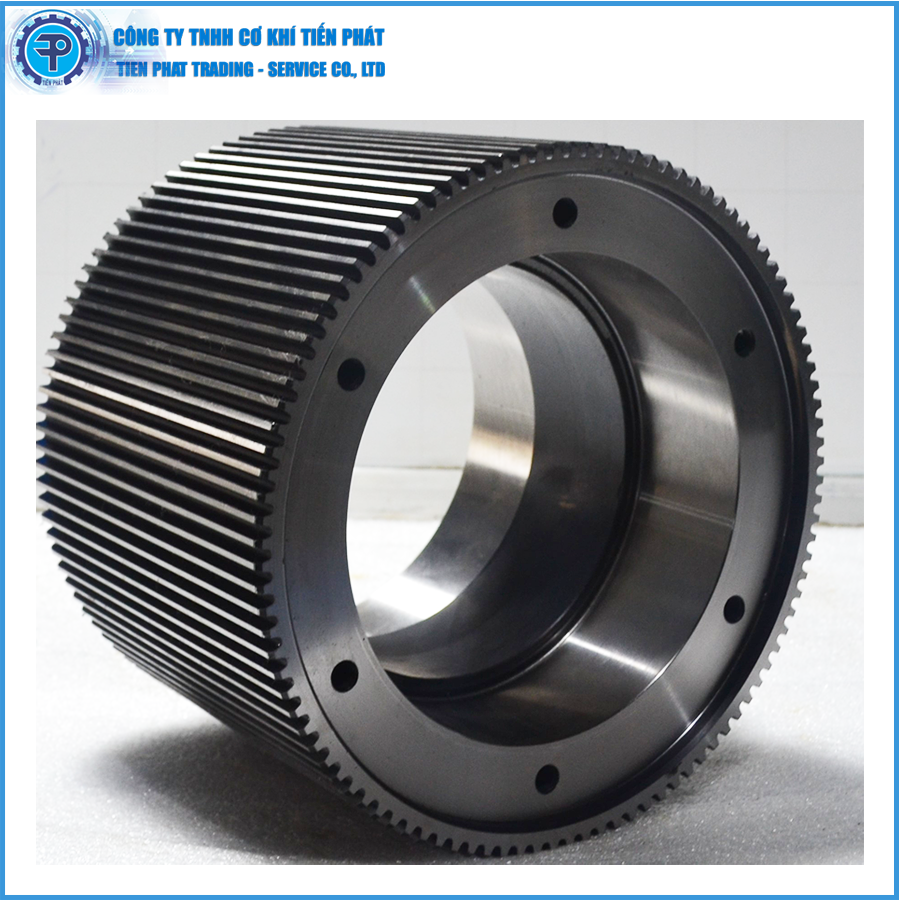

The machining of Steam Lock – Shear Lock is a critical technical process in extruder machines, playing an essential role in controlling steam, pressure, and shear force within the extrusion chamber. This process requires high precision, in-depth knowledge of material properties, thermal resistance, friction resistance, and extensive practical experience in the mechanical processing of livestock and aquaculture feed. Tien Phat Mechanical selects high-quality steel billets with excellent heat resistance, pressure resistance, and wear resistance, suitable for the continuous and harsh operating conditions of extruder machines.

At Tien Phat Mechanical, Steam Lock – Shear Lock components are precisely machined using advanced CNC systems, ensuring strict compliance with technical designs, optimal working clearances, and high concentricity. These factors enable effective control of steam and material flow within the extrusion chamber, maintain stable pressure, and generate appropriate shear force during the extrusion process. The products undergo controlled hardening heat treatment to optimize mechanical properties, enhance resistance to heat and friction, and extend service life.

In addition, a rigorous quality control system is applied throughout the entire manufacturing process—from dimensional inspection, assembly clearance, and concentricity checks to hardness testing and other critical technical parameters—supported by modern measuring and inspection equipment. This ensures that every Steam Lock – Shear Lock delivered meets technical requirements and operates reliably and durably over long-term use.

Technical Specifications

-

Material: Alloy Steel

-

Hardness: 54–56 HRC

-

Heat Treatment: Vacuum heat treatment

-

Types: Customized based on machine models and customer requirements

Ordering & Delivery

Optimized processes to minimize customer downtime:

-

Quotation: Detailed response within 24 working hours

-

Manufacturing Lead Time: 30 -60 days, depending on raw material

(urgent orders can be expedited) -

Shipping:

-

Domestic: Door-to-door delivery within 2–5 days, depending on location

-

Export: Support for various Incoterms (FOB, CIF, CIP, DDP, etc.) upon request

-

-

Packaging: Rust-preventive oil coating, shrink wrapping, and sealed wooden crates compliant with export standards

Technical Support

Remote online technical support or on-site assistance at the customer’s factory, depending on requirements.

Commitment

With a team of experienced and professional engineers and technicians, Tien Phat ensures finished products with high precision that fully meet technical requirements and respond quickly to customer needs.

We place trust and reliability at the core of our operations and are committed to completing all orders on time while maintaining the highest quality standards. In the event of equipment issues, we pledge to provide prompt solutions and timely support to minimize downtime and losses for our customers.

Contact Information

Tien Phat Trading & Service Mechanical Company Limited

- Head Office: 237A National Highway 1K, Linh Xuan Ward, Ho Chi Minh City, Vietnam

- Branch Factory: No. 3, Cay Tram Residential Area, Tan Khanh Ward, Ho Chi Minh City, Vietnam

- Website: https://cokhitienphat.com

- Email: cokhitienphat@gmail.com

- Phone: (+84) 937 059 288

- Facebook: facebook.com/cokhitienphat

Tiếng Việt

Tiếng Việt

Be the first to review “Steam lock – Shear lock”