Pellet Mill Ring Die

Products

Subscribe To Our Weekly Newsletter

No spam, notifications only about new products, updates.

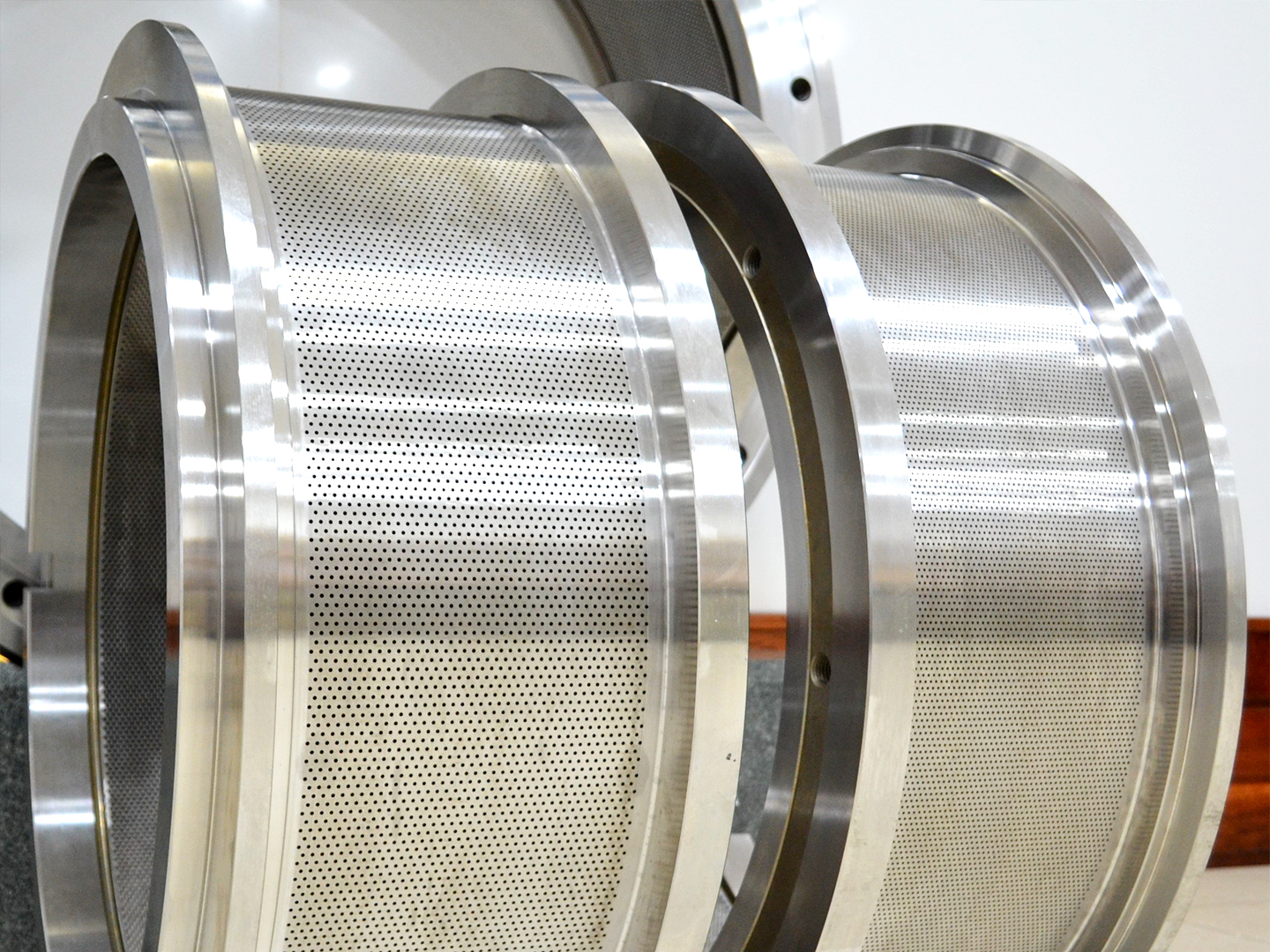

Pellet Mill Ring Die

Ring Die are core components of pelletizing machines, primarily used to shape raw materials into pellets. As the material is forced through the die holes by the rollers, the die plays a vital role in determining the size, efficiency, and quality of the final feed pellets.

Description

Ring Die are core components of pelletizing machines, primarily used in the production of animal feed, biomass pellets, poultry feed, aquafeed, and more. Each die is custom-designed based on specific customer requirements in a wide range of sizes, hole configurations, and diameters.

We are a trusted partner, supplying high-quality dies, spare parts, and machine components to leading animal feed and aquafeed manufacturers in Vietnam, as well as to multinational corporations worldwide.

From raw material selection to after-sales service, TIEN PHAT is dedicated to every step of the process to deliver the perfect ring die for each customer.

At TIEN PHAT, we supply premium dies, replacement parts, and machine components to leading animal feed and aquafeed producers in Vietnam and multinational corporations around the world—helping them achieve greater durability and performance in every production cycle.

- Origin: Vietnam.

- Brand: TIEN PHAT MECHANICAL VIETNAM CO., LTD.

- Condition: New (made to order).

- After-Sales Service: 24/7 support.

Dimensions: Customized upon customer request (based on customer drawings/specs).

Material: Stainless steel.

Hardness (after heat treatment): HRC 51–52.

Types:

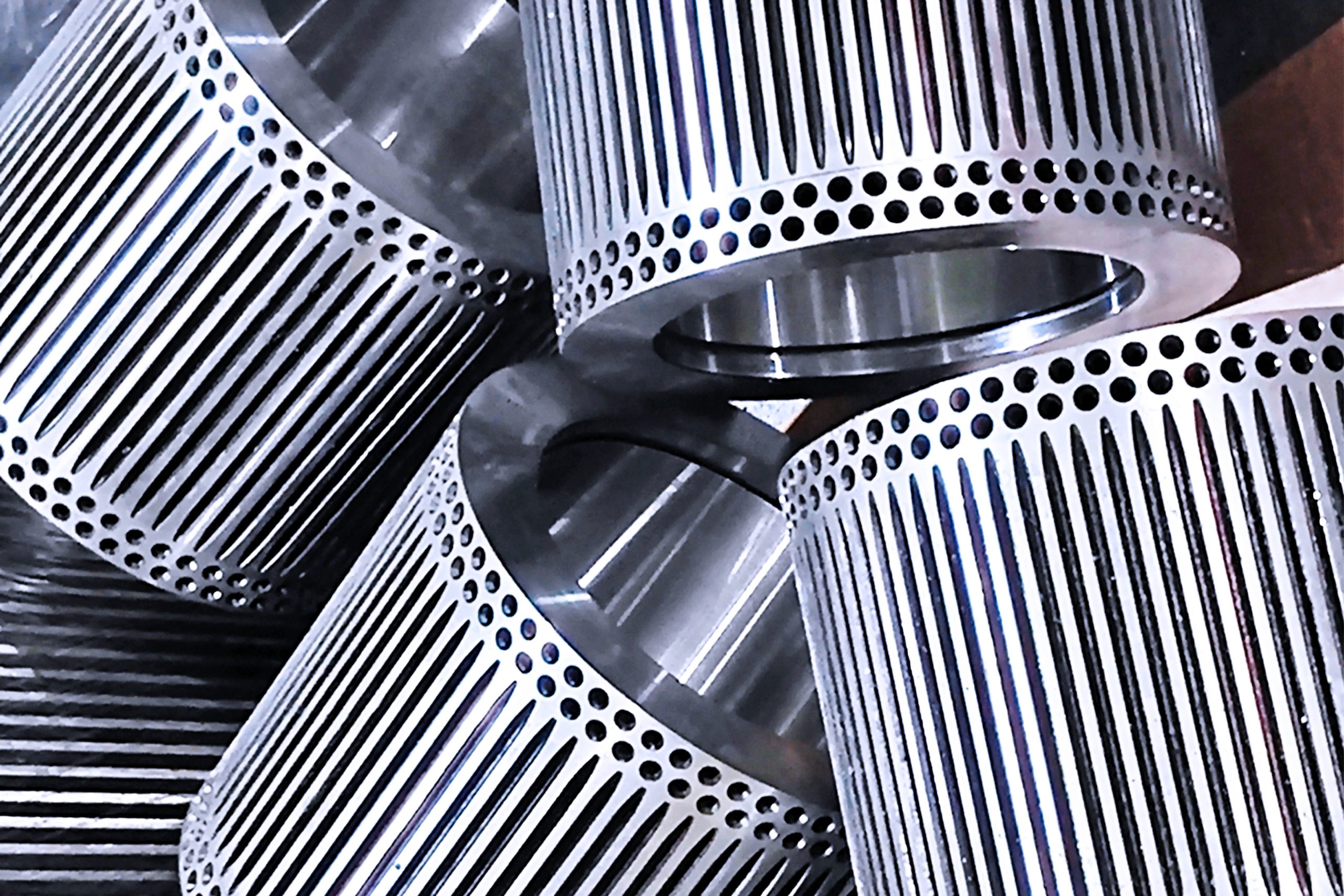

Pellet mill dies with hole size 1.0mm – 2.0mm: Ideal for producing aquafeed, especially shrimp feed.

Pellet mill dies with hole size 2.0mm – 8.0mm: Suitable for manufacturing animal feed for livestock and poultry.

Pellet mill dies with hole size 5.0mm – 10.0mm: Designed for fertilizer pellet production and biomass fuel pellets (e.g., wood pellets).

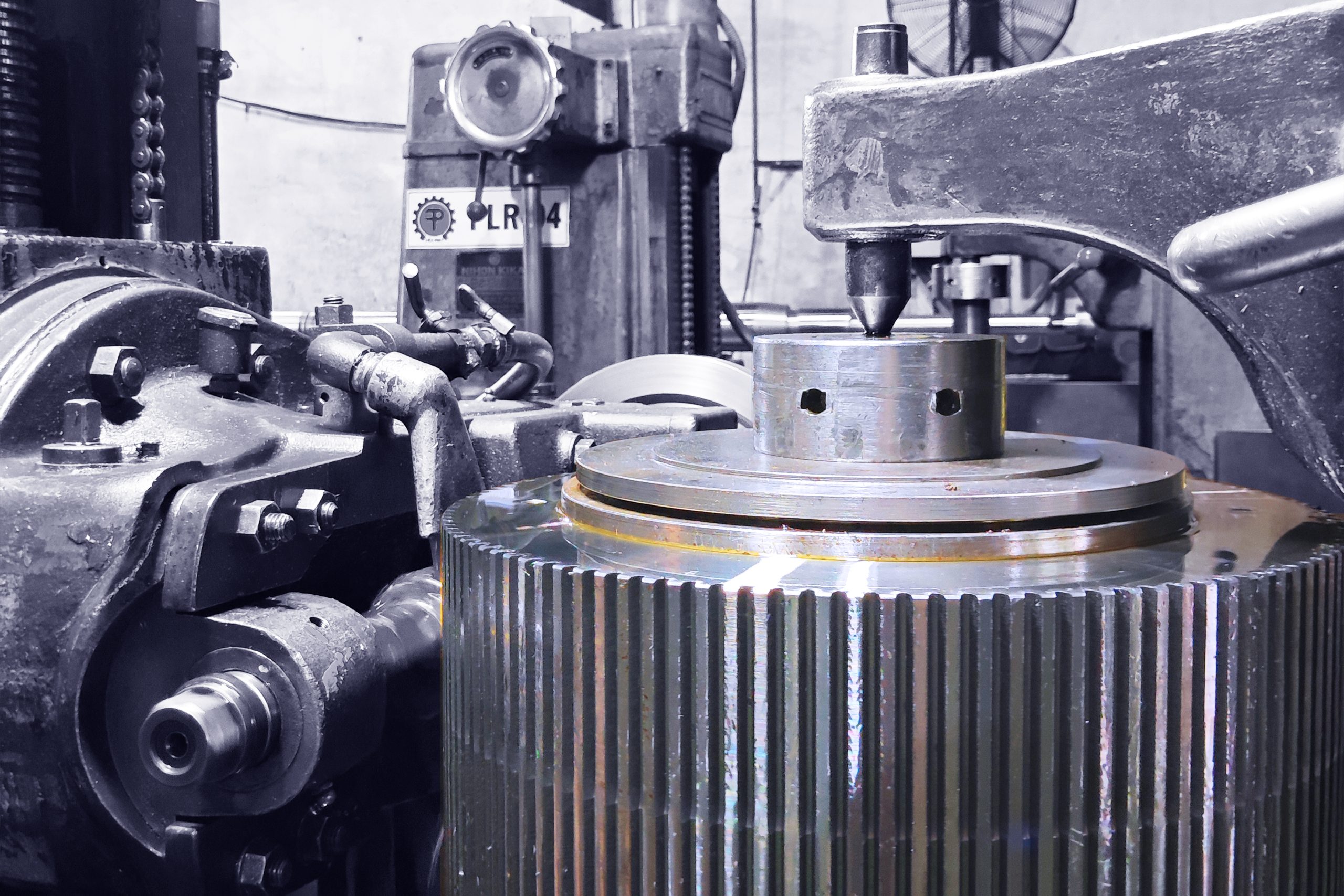

Manufacturing Method: Fully CNC-machined and heat-treated.

Animal Feed Production: Efficiently compress raw ingredients into uniform pellets for poultry, livestock, and aquaculture feed.

Aquafeed Processing: Tailored for high-moisture, high-protein formulations specific to shrimp and fish feed.

Biomass Fuel Pelletizing: Applied in the production of wood pellets, rice husk pellets, and other renewable energy fuels.

Fertilizer Pellet Production: Suitable for pressing organic and compound fertilizers into stable granules.

Custom Pellet Formulations: Designed to accommodate specialized or client-specific materials and pellet shapes.

Manufacture Process

Materials

High-quality alloy steel, engineered with high precision. All components are produced in strict accordance with technical drawings and process documentation.

Deep Hole Drilling

Performed using high-precision multi-station CNC gun drilling machines for accurate die hole positioning.

Heat Treatment

Achieves uniform hardness across the die, ranging between HRC 51–52, with a maximum deviation of HRC ±2.

Our Advantages

● We are a large-scale enterprise with extensive manufacturing capacity and in-depth industry experience.

● We produce custom rollers based on customer technical drawings, delivering the highest-quality spare parts tailored to their specific requirements.

● Our rollers are manufactured using premium-grade materials, available in all sizes and types compatible with renowned pellet mill brands such as Andritz, Bühler, CPM, Van Aarsen, and more.

● As a genuine manufacturer, we maintain full control over product quality throughout the entire production process. Our rollers offer longer service life than comparable products on the market. Our engineering team designs the most suitable rollers based on each customer’s production needs and provides expert consultation on roller selection.

● We also provide inventory planning services to help customers avoid production disruptions.

Contact Us Now

Enter your inquiry details. We will reply you in 24 hours.

Related Posts

[Case Study] Xử lý tình trạng bể khuôn ép viên – không phải bằng cách làm dày hơn, mà bằng giải pháp đúng hơn

Khám phá cách chúng tôi giúp cho khách hàng của

Thủy sản Việt Nam ‘đứng ngồi không yên’ khi Mỹ áp thuế các nước

Ngành thủy sản Việt Nam sau cú bứt phá gần

TRỤC LỆCH TÂM

Cơ Khí Tiến Phát là đơn vị chuyên sâu trong lĩnh vực nghiên cứu và sản xuất khuôn và phụ tùng máy ép viên cho các dòng máy của những thương hiệu lớn trên thế giới. Phù hợp cho các doanh nghiệp sản xuất cám tôm và viên gỗ.

Pellet Mill Roller Shell

Cơ Khí Tiến Phát là đơn vị chuyên sâu trong lĩnh vực nghiên cứu và sản xuất khuôn và phụ tùng máy ép viên cho các dòng máy của những thương hiệu lớn trên thế giới. Phù hợp cho các doanh nghiệp sản xuất cám tôm và viên gỗ.